Ottobock Media Day 2025

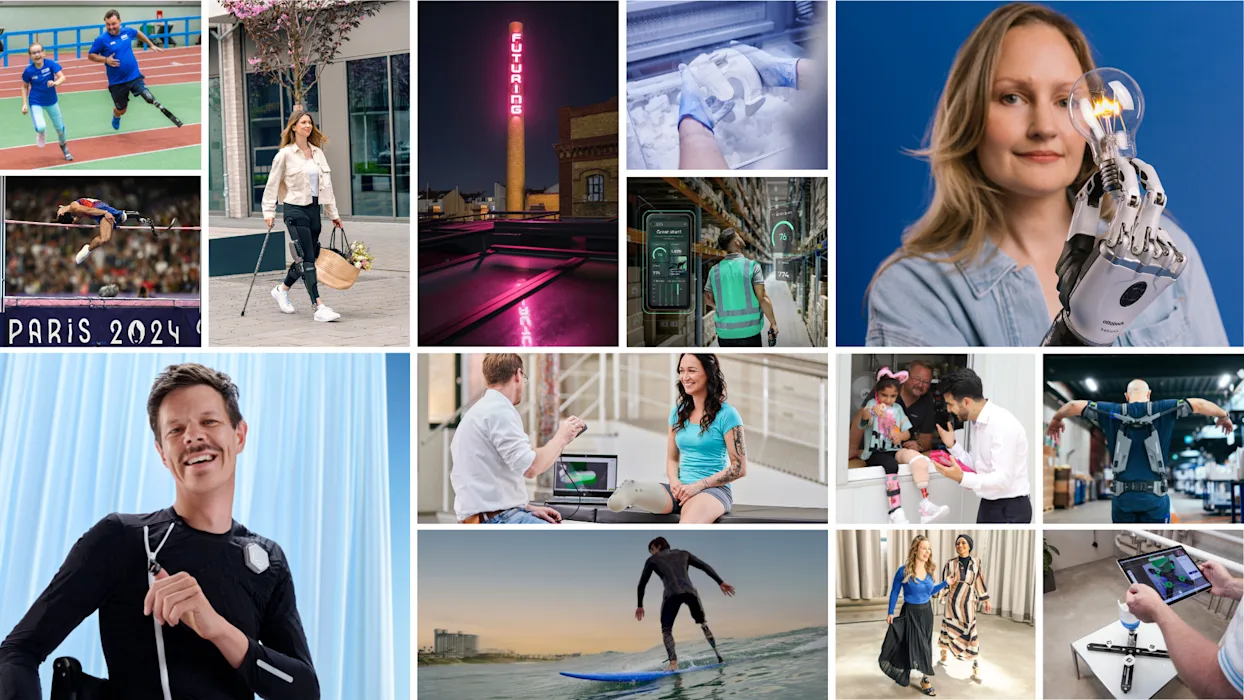

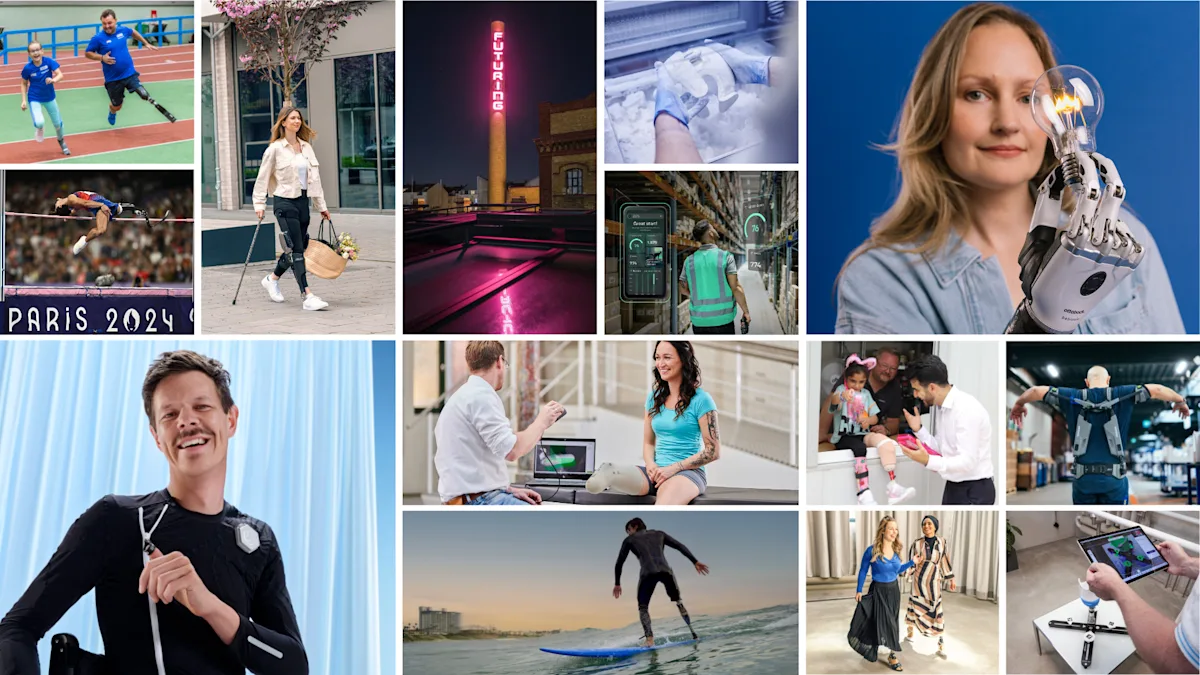

Future is created where boundaries are redefined. We develop technologies that enable people with disabilities to improve their quality of life and empower themselves.

Experience how we brought our vision of ‘Human Empowerment’ to life at the Ottobock Media Day.

Watch now the after movie!

We empower people

For over 100 years, we put people first in everything we do. It all began in Berlin in 1919 with prosthetics for war victims. Today, Ottobock helps people with disabilities become more mobile with "wearable human bionics"—technological devices such as prostheses and orthoses. Many users are now represented in Paralympic sports, pop culture, and fashion. They are part of an empowerment movement. Digitalization, artificial intelligence, and cutting-edge technologies are shaping a 360° connected ecosystem between users, orthopaedic professionals, and medical technology companies.

Innovations for Inclusive Space Exploration

The 44-year-old multitalent, born in 1981, now lives with his wife and three children in Bonn, home to the German headquarters of the European Space Agency. In 2022, the ESA selected John McFall to explore the feasibility of space missions for people with physical disabilities.

He and Ottobock have worked closely together for about ten years, both in marketing and product development. McFall, for instance, is a test user of the new Genium X4 prosthetic knee joint, designed for highly active individuals, and contributes valuable insights to the product development process. Now, the collaboration with Ottobock’s global development organisation is reaching a new level—a groundbreaking project: a long-term mission to the International Space Station (ISS).

Human empowerment through imagination and innovation

In addition to our five program highlights, we offer interactive stations about different topics that you can visit flexibly. Experts and users will be available for interviews.

How can prosthetic and orthotic devices be controlled more intuitively? How can we further improve the comfort for users? Which role do neural connections play? And how do we make it possible for a “foreign body” to give us feedback? These questions are in the focus of our research – together with partners such as BionicSkins, MuscleMetric and Onward.

Exchange ideas with our experts. Find out what Ottobock is currently working on and what innovative developments await us in the future.

Learn more about our latest research activities:

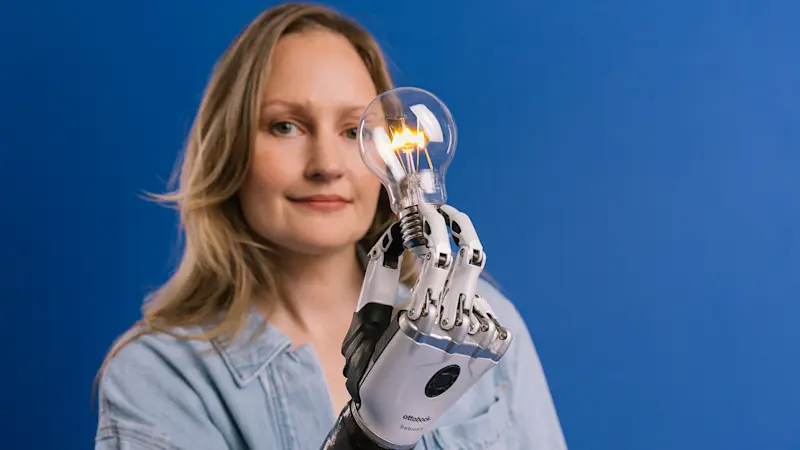

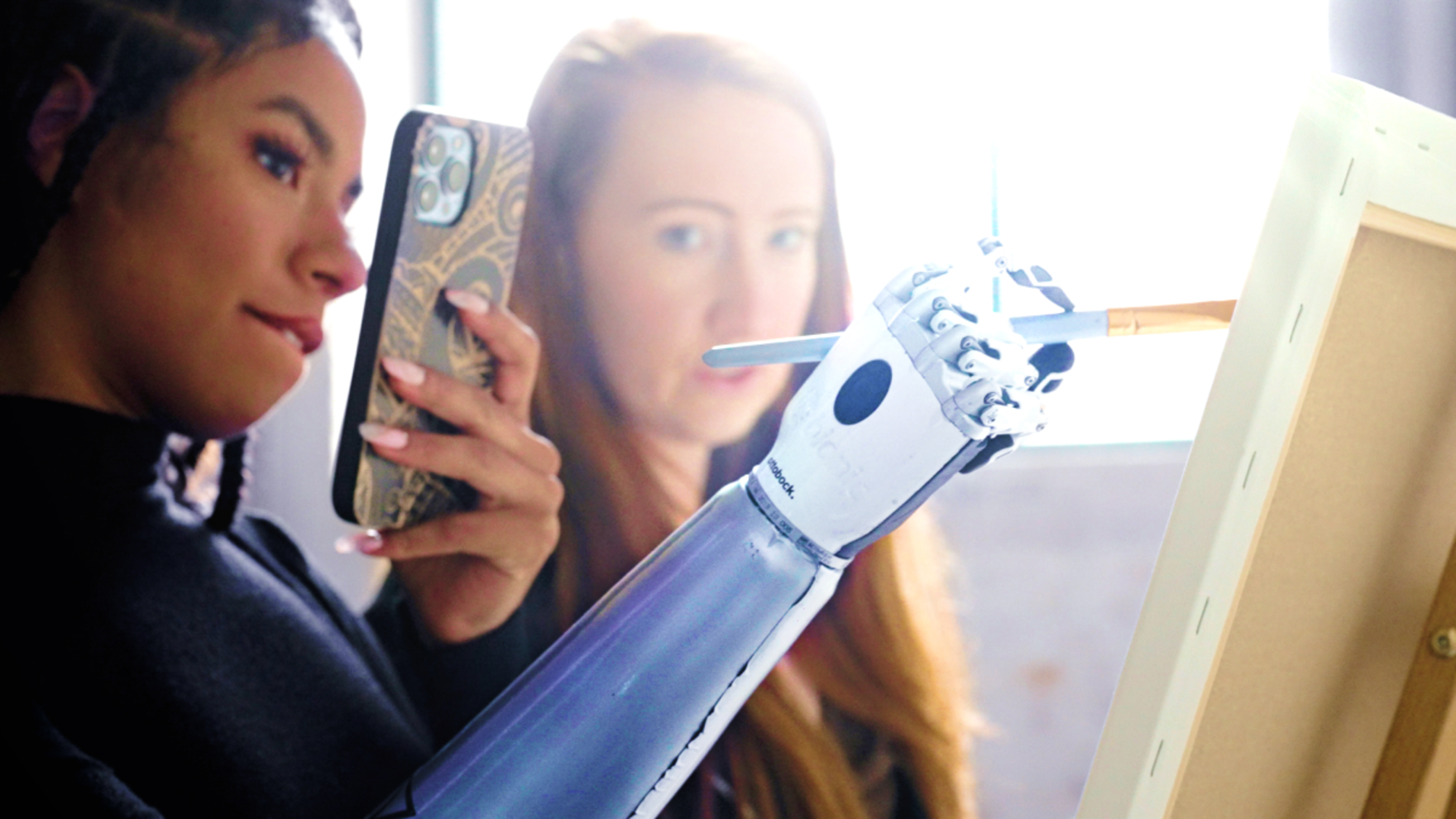

Smart hand prostheses

Myoelectric arm prostheses convert muscle impulses into electrical signals and transmit them to the prosthesis electronics as control commands. Electrodes record the impulses on the skin and directly translate them into a movement of the prosthetic hand. Thanks to AI, smart control technology learns to interpret the user’s individual movement patterns, assigning them to a specific prosthesis movement.

With the speedhand, myosmart control and connectgrip app, Ottobock now offers a new fitting solution that is fully tailored to the individual needs and unique signals of every user – and can be operated completely intuitively. Try it out for yourself!

Digital treatment with 3D technologies

Digitalisation is creating new expectations and opportunities. Fast and customised production – that’s the future of orthopaedic technology. Digital solutions are counteracting the increasing shortage of skilled workers as well as the prevailing time pressure in patient care.

Experience the complete digitalised fitting process for the lower limbs, from a 3D scan of the residual limb to digital modelling to 3D printing of the prosthetic socket, to the millimetre-precise transfer of a 3D model from the test socket to the definitive socket. Get first-hand impressions of the benefits of the cutting-edge treatment from digital expert Uli Maier and user Silvio Otto.

Uli Maier, O&P professionalAs an O&P professional, I was initially somewhat sceptical about digitalisation. However, I was won over when my first user reported that their 3D-printed liner actually fit better.

More information about the topic

MyFit TT

Thanks to the digitally modeled MyFit TT test- and 3D-printed definitive sockets, the fitting process can be made more efficient.

Thanks to the digitally modeled MyFit TT test- and 3D-printed definitive sockets, the fitting process can be made more efficient.

How 3D scanners and printers are revolutionising fitting for patients

Fast and customized production is the future of orthopedic technology. The iFab has digitized the complete fitting and production process.

Fast and customized production is the future of orthopedic technology. The iFab has digitized the complete fitting and production process.

The future of orthopaedic technology

Here’s how apps, smart sensors, microprocessors, 3D printers and 3D scanners help people with and without disabilities today: discover innovations from Ottobock.

Here’s how apps, smart sensors, microprocessors, 3D printers and 3D scanners help people with and without disabilities today: discover innovations from Ottobock.

3 results out of 3

Innovation you can feel with exoskeletons

The market leader for industrial exoskeletons – SUITX by Ottobock – is presenting two groundbreaking innovations for more ergonomic workplaces, which will be launched in autumn 2025. Both solutions set new standards in health promotion based on AI.

The IX BACK VOLTON is the first intelligent back-exoskeleton in the SUITX by Ottobock portfolio. A smart power boost adapted to movement reduces back strain during lifting processes by up to 17 kilograms. AI recognises the user’s movement patterns and adjusts support without changing natural movements.

AIRGO XP is an AI-supported solution for ergonomic optimisation in the workplace. A tracking system analyses movement patterns and identifies health risks. The data is recorded via an app integrated into a vest and provides employees with direct feedback and individual training recommendations.

Try out the IX SHOULDER AIR, which makes overhead work more comfortable and healthier.

No more compromises thanks to adaptive fashion

We showcase fashion that was developed together with our users. The collaboration between Zalando and Ottobock resulted in clothing that not only look good but are also well-thought-out: concealed magnetic closures instead of classic buttons, cuts that make it easier to put on and take off, and materials that combine comfort and style. What makes these pieces special? The people they were made for were directly involved in the design process.

Our adaptive fashion portfolio is complemented by another highlight: the Taleo Adjust prosthetic foot. It gives users greater freedom in their choice of shoes – from trainers to heels (0–7 cm).

Sport as part of our DNA

For more than 30 years, Ottobock has been committed to making sports easier for people with disabilities – from broad-based to competitive sports. Learn about our wide range of initiatives that promote and support sports – from the Running Clinics and Talent Days to our rental model for sports prostheses mysportsbox to our commitment to the Paralympic Games as a technical service partner. We share insights into current plans for the 2026 Paralympic Winter Games in Milano Cortina and the 2028 Summer Games in Los Angeles.

Back to life

The right treatment is a key factor for getting people back to independent everyday lives after an accident, disease or operation. It also promotes the best possible participation in society. Product solutions that meet needs and an interdisciplinary rehabilitation process offer efficient and effective support here.

What are the requirements and challenges of comprehensive rehabilitation processes with orthopaedic technology devices? We share examples of modern fitting solutions that can be adapted to various mobility needs.

Ayleen's journey to an upright life

The Marburg woman has been paraplegic since 2020 due to a chronic spine disease in both her legs. She stood up for her own treatment and thanks to special high-tech orthoses, she is now able to walk again and travel the world – places that aren’t barrier-free and have long been denied her. As a speaker, Ayleen shares her experiences with those affected – and fights against taboos and to raise awareness.

Help for people in crisis areas

The war in Ukraine, the aftermath of the earthquake in Turkey and the devastating situation in the Gaza Strip are currently affecting thousands of people. Countless injured people depend on medical technology devices. Ottobock and the Ottobock Global Foundation are working together with support and fundraising campaigns to provide as many people as possible in crisis regions with orthopaedic devices.

To counteract the shortage of skilled workers in crisis regions, Ottobock provides expertise by transferring knowledge. In addition, the medtech company equips workshop and patient care containers for treatments directly on site. The Ottobock Global Foundation uses donations to finance medical technology devices and fittings, especially for children and adolescents in need. In doing so, Ottobock and the Ottobock Global Foundation rely on a global care network and partnerships with international aid organisations.

exopulse suit – next generation

Muscle cramps, movement disorders, chronic pain – symptoms like these restrict the daily lives of many people with neurological diseases. At Media Day 2025, Ottobock is presenting the new generation of a medical device that can improve quality of life: The exopulse suit is intended for children and adults with cerebral palsy, multiple sclerosis, stroke and other neurological disorders as well as fibromyalgia patients.

With 50 embedded electrodes, the suit relieves spastic-related tension and related pain quickly and sustainably via gentle, targeted electrical stimulation, as well as fibromyalgia symptoms such as fatigue and pain.

Kerstin has less spasticity pain and an improved quality of life

Kerstin was diagnosed with multiple sclerosis when she was only 17. Her condition has deteriorated so much that she is permanently dependent on a wheelchair. Pain is with her constantly. Kerstin had to take up to 30 tablets and medical anaesthetic substances every day.

Now 40 years old, she learned about Ottobock’s Exopulse Mollii Suit on Instagram and tried it out. Kerstin was overwhelmed by the results, experiencing considerably less pain and spasticity. The neuromodulation suit even lets her go on holiday with her family again.

Hands-free on the road with Genny Zero

The innovative e-mobility device uses advanced stabilisation technology that allows users to move around hands free. Control is intuitive by shifting the upper body – which relieves strain on the arms and shoulder joints at the same time. Genny Zero provides reliable stability in an upright position while balancing on two wheels – whether on the sidewalk or cobblestones, over curbs and slopes.

Try the Genny Zero for yourself and experience the unique driving experience of the e-mobility aid.

13 facts about Ottobock

The company was founded in Berlin in 1919 to provide prostheses for war veterans during World War I.

Näder Holding GmbH & Co. KGaA holds 100 per cent of Ottobock SE & Co. KGaA, which belongs to the Näders family of owners, who are the direct descendants of Otto Bock, the company founder.

The company’s headquarters are located in Duderstadt, Germany.

Whether prostheses, orthoses, wheelchairs, exoskeletons, apps or milling machines: Ottobock’s product portfolio today includes around 700 product ranges.

Since 2012, SUITX has been developing so-called ‘wearables’ to make everyday work easier for people who do physical labour. The team draws on Ottobock’s more than 100 years of experience in biomechanics and orthopaedic technology in the development of new solutions.

In 2015, Professor Hans Georg Näder founded the Ottobock Global Foundation to provide children in need with prostheses, orthoses and wheelchairs – for example in Gaza, Turkey and Lebanon.

We have been supporting athletes at the Paralympic Summer and Winter Games with our free technical service for more than 30 years.

106 years

since the company was founded, people have come first in everything we do.

1988

started our commitment to the Paralympic Games.

9,100

people work for Ottobock around the world.

400

own patient care centres operated by Ottobock worldwide.

2,500

patents issued for prostheses, exoskeletons, orthoses and wheelchairs.

1.6 billion EUR

turnover in 2024.

Management of the company

Ottobock is a partnership limited by shares and is not listed on the stock exchange (SE & Co. KGaA). 100 per cent of the shares are held by Näder Holding, which is owned by the Näder family.

Ottobock is a partnership limited by shares and is not listed on the stock exchange (SE & Co. KGaA). 100 per cent of the shares are held by Näder Holding, which is owned by the Näder family.

Convincing facts and authentic emotions

Ottobock combines a human touch with growth and financial strength.

Ottobock combines a human touch with growth and financial strength.

Sharing technical expertise

We make our contribution to training, continuing education and improving the quality of treatment.

We make our contribution to training, continuing education and improving the quality of treatment.

3 results out of 3

Press contact

Please contact us if you have any questions regarding the Ottobock Media Day 2025. We can provide you with first-hand information and coordinate interviews with our experts and users.

Here you can find our direct contact details for queries.

Merle Florstedt