A pioneering spirit to become the leading innovator.

Medical technology in tune with the times.

How do we make genuine progress of what is technically feasible? Something that helps people retain or regain their mobility? Since 1919, we at Ottobock have been developing solutions inspired by the human body. In doing so, we not only want to meet standards in orthopaedic technology, we want to think ahead. In 1997, Ottobock presented the first microprocessor-controlled lower limb prosthesis C-Leg. To this day it remains the worldwide technological standard. By means of a self-learning system, our bebionic prosthetic hand revolutionised life after an amputation. And the waterproof Genium X4 joint makes swimming, cycling and jogging possible.

Data-based development and artificial intelligence (AI) make movements with prostheses more natural and safer. Together with research partners around the world, we are developing new fields such as neuro-rehabilitation and quantum sensor technology.

Mor innovations that benefit people with handicap.

Collaboration for inclusive space exploration.

A project whose gained insights could not only pave the way for future astronauts with physical disabilities but also drive innovation in prosthetic care here on Earth.

Ottobock and John McFall have enjoyed a close partnership. The Brit lost his right leg in a motorcycle accident at the age of 19. Today, he’s a trauma and orthopaedic surgeon, a former Paralympian – and the first astronaut with a physical disability. Now, this collaboration is entering a new dimension: a potential long-duration mission aboard the International Space Station (ISS).

In 2023, the European Space Agency (ESA) selected Ottobock as the official supplier for McFall’s specialised prosthetic solutions for space. The requirements are extreme: every component must pass rigorous safety checks and be certified. Ottobock engineers, material specialists and prosthetists work with ESA safety teams and the astronaut to develop space-ready solutions that perform reliably and in safety-critical situations. This includes comprehensive risk analyses, laboratory testing and parabolic flights to simulate weightlessness.

Sports prosthesis for treadmill training featuring a softer running blade tailored to the forces in microgravity.

High-tech Genium X4 prosthesisfor everyday tasks and strength training aboard the ISS, with software adapted for weightlessness.

Mechanical prosthesis for launch and landing without electronics, ensuring maximum safety.

3D-printed protective covershields for both the spacesuit and the prosthesis, made from flexible material used in sports applications.

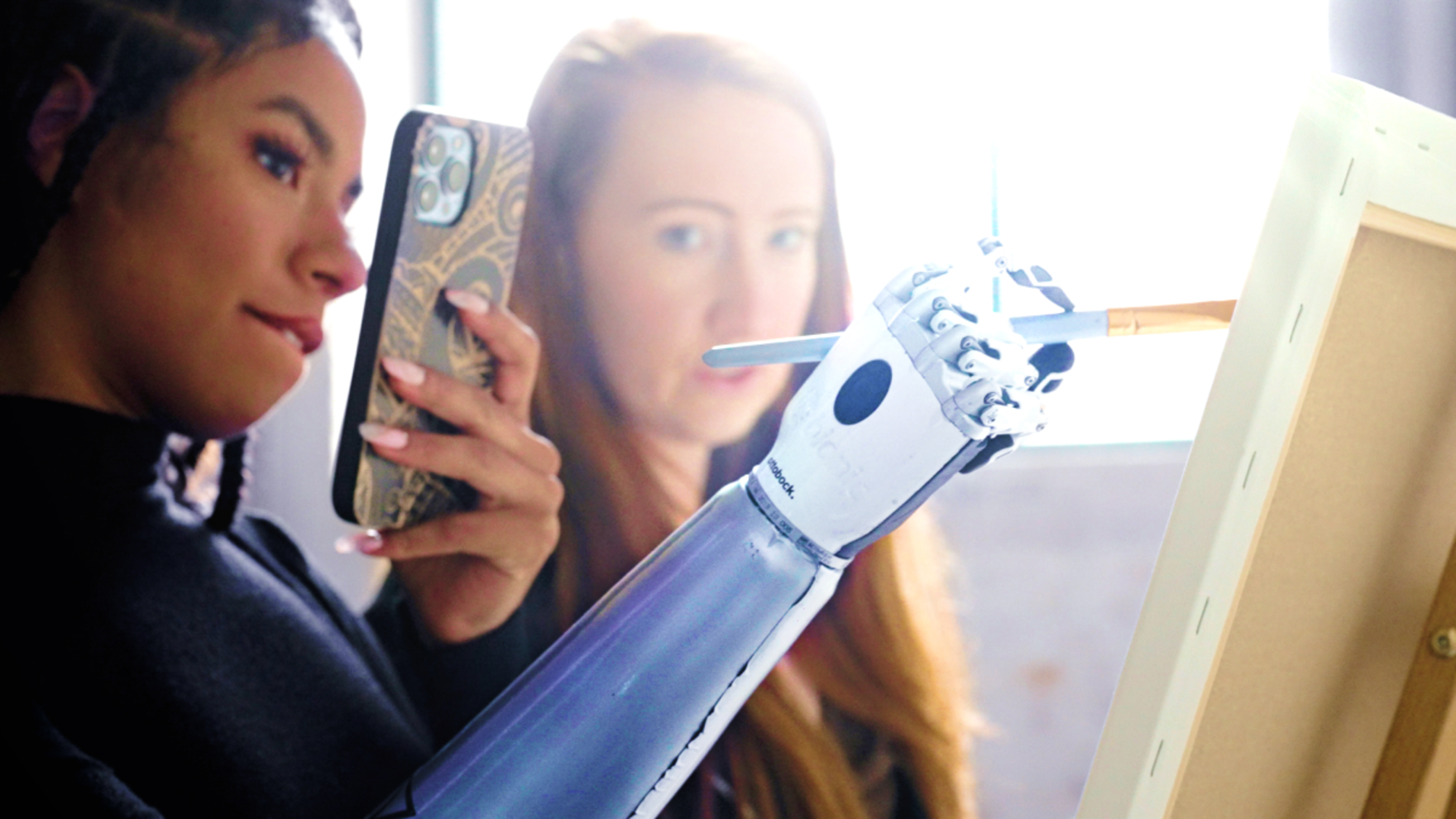

Combination of body and technology.

Michael Friedrich Russold, Research and DevelopmentThe next exciting step in the future will be prostheses that can "feel". Ideally, the user should feel that the prosthesis or orthosis is part of their own body – a natural extension of the body, so to speak.

Clinical studies.

How much more mobile does a person become thanks to their new prosthesis? How much is the danger of falling reduced? In figures, how much is quality of life improved? Ottobock makes progress measurable: our research examines products, treatment methods and rehabilitation successes. This serves to provide safety, trust and reimbursement by health insurance companies.

Networking knowledge, learning together.

"Outside-in" means developing groundbreaking technologies – and being open to knowledge outside the company. Our researchers collaborate with bright minds, universities and institutions from all over the world, for example:

Ottobock is conducting research on intuitive prosthesis control using the human-machine interface, for example with the MIT startup MuscleMetrix or the neurotechnology company Phantom Neuro from Austin, Texas.

In the HGN Lab at the University of Utah in Salt Lake City, Ottobock supports the development of the next generation of bionic limbs.

As part of the project "QHMI – Human Machine Interface Based on Quantum Sensors", Ottobock is developing mind-controlled prostheses based on quantum sensor technology.

The EU-funded HARIA project is working on wearable sensorimotor interfaces and robotic limbs for humans with upper limb disabilities.

In purchasing the company, Ottobock and Onward Medicaldeveloping innovative NeuroTech solutions to restore the mobility, function and independence of people with paraplegia.

Ottobock supports the research of the Shirley Ryan AbilityLab in Chicago with the Max Näder Center for Rehabilitation Technologies and Outcomes Research.

For its collaboration with the AutoAssist research project, Ottobock is working on ultrasound exams, advanced intent recognition and virtual reality.

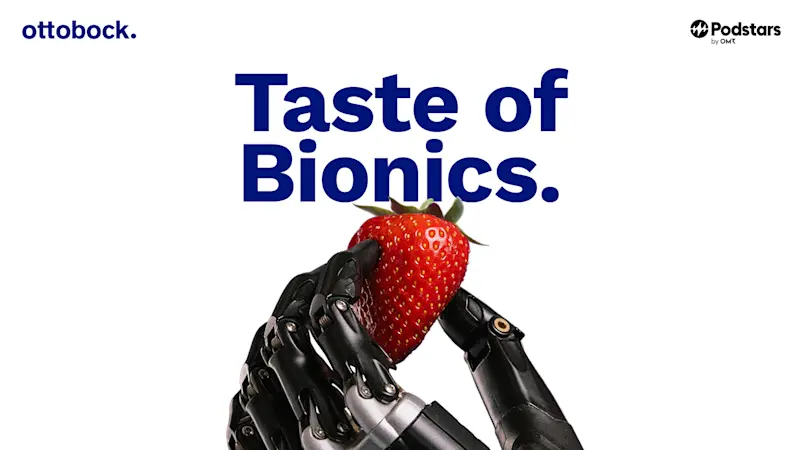

Ottobock's podcast with Ranga Yogeshwar.

Taste of Bionics is Ottobock's new podcast, in which the renowned science journalist Ranga Yogeshwar takes a deeper look at bionics and the connection between humans and technology.

In the eight episodes of the podcast, experts of the O&P world discuss groundbreaking topics such as modern prosthetics, exoskeletons, neural interfaces, human-machine interaction, artificial intelligence, as well as medical technology innovations that improve people's lives.

Helping people to remain mobile for a long time.

Ottobock doesn’t just help people regain their mobility, we help them to remain healthy for as long as possible. Exoskeletons take the strain off strenuous activities.

A digital think tank in the heart of Berlin.

The premises of the former Bötzow Brewery are home to Ottobock’s digital research lab, where the medtech company focuses on the topics that are shaping tomorrow's world – digitalisation, for example.

At Bötzow, Ottobock is developing a digital ecosystem and the networked Patient Care clinic of the future – with everything from pioneering high-tech manufacturing technology such as 3D printing to holistic, digitalised fitting plans to smart sensors for products. The aim is to help patients get treatment faster and more easily, customise prostheses more highly and connect people via various platforms.

Your contact for more information on research & development.

Additional topics.

The future of orthopaedic technology

Here’s how apps, smart sensors, microprocessors, 3D printers and 3D scanners help people with and without disabilities today: discover innovations from Ottobock.

Here’s how apps, smart sensors, microprocessors, 3D printers and 3D scanners help people with and without disabilities today: discover innovations from Ottobock.

Award-winning company

Ottobock is an honorarium laureate for outstanding work in various disciplines.

Ottobock is an honorarium laureate for outstanding work in various disciplines.