Design of the new C-Leg: “Expressing personality is a deeply rooted need”

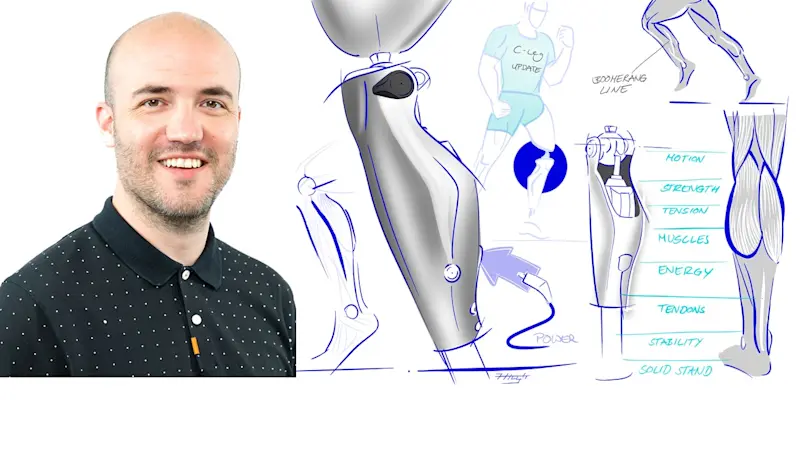

Interview with Ottobock Designer Andreas Hogh about the design of the new C-Leg

Twenty-five years ago, Ottobock launched the first computer-controlled leg prosthesis in the market: The C-Leg. It sets standards to this day – also in terms of its design. The design came from design agencies for a long time. Today, more in-house designers are developing the characteristic look of Ottobock prostheses. Among them is the industrial designer Andreas Hogh from Vienna. He is involved in the design of prostheses such as the latest C-Leg update, which will be launched on 10 May 2022. In this interview, he talks about what matters, how the appearance has changed over time and how prosthetic design in films and video games has contributed.

The first prostheses were simple devices made of wood. How has prosthetic design changed compared to the early days?

When you look at the history of prosthetics, it all started with pragmatic solutions. Ottobock laid the foundation for modern prosthetic design with the C-Leg in 1997. Everything builds on that. Today more than ever, people are trying to get closer to the human anatomy, with 3D printing playing a role. Forms that could not be realised before can be easily manufactured.

What forms are these, for example?

Structural forms on a bionic basis, such as frame structures, which are computer-simulated for strength. This can be imagined as the beams of a half-timbered house or bone structures. In prototype construction, we can test the shield inserts of the joints very quickly in a near-series quality. This makes the work easier because we can make changes faster.

Is it possible to draw parallels between prostheses and other products?

Perhaps the development cycles from model series to model series are comparable for cars. Design trends influence perceptions. The C-Leg design of 1997 has changed a lot compared to today, just as the VW Golf of yesteryear has changed. The design fits with its time. Curvilinear forms and dynamic surface reflections are used more commonly in prostheses today than they were in the past. Without disregarding the human model, I think it's OK to see their technical character.

What was important in the design of the first C-Leg 25 years ago and the latest C-Leg from 2022?

We have the longest history with the C-Leg. Therefore, we took care that an evolutionary step is visible, based on the previous models. The carbon frame of the C-Leg reflects dynamics, representing activity.

This can be seen in the shape of the kneecap and in calf muscles highlighted by a contour edge. The lateral surfaces are also more curved. With this deliberately set contour edge, we join the knee axis with the axis of the hydraulics. The colour scheme has become more differentiated as well.

How did you design the new C-Leg?

The product evolves step by step: Sometimes you make models out of rigid foam as a decision-making aid. Sketching and modelling in CAD help with product development. I follow the anatomy of the human body, such as musculature, tendons and the like. Nevertheless, I try not to copy this one to one. Rather, I develop a controlled, defined, organic form. It is after all a technical product, and this can and should be apparent.

The shield inserts on the front of the prostheses can be painted in the new C-Leg update. Why?

We did this to create a kind of individualisation. The standard shield inserts are available in different colours and in graphic patterns. To express one's personality is a deep-seated need.

You keep seeing models with prostheses that present the “high-tech look.” Is there a general trend towards the conscious display of the prosthesis?

We monitor trends very closely and respond to them where we can. Many people are more progressive with their prostheses than they were a few years ago. Social media also drives this perception. Perhaps one could even go so far as to call this a trend towards education or de-stigmatisation. Nothing gives us more pleasure than to see that a person likes to wear our product and is proud to show it off.

What examples can you think of?

Nike presented models with prostheses and designed the “Nike Go FlyEase” with a slip-in mechanism, so that arm amputees do not need hands to tie the shoes. For hand prostheses, which are covered by clothing even less frequently, there is also a noticeable trend in favour of a high-tech look. The film and computer game industry has changed people's viewing habits and created more acceptance for the tech look.

What role do computer games and movies play?

Time and again, we see people from the cosplay scene recreating bionic limbs or entire suits of game characters that actually work. A company has also functionally recreated a hand prosthesis from the game “Deus Ex.” This again is a good example of how 3D printing has revolutionised the industry. That's good for an eye-catcher, but our approach at Ottobock is fundamentally different. We want to empower people with our products to take back their everyday lives.

How could the desire for individuality in the O&P industry be met even more effectively?

Through iFab, meaning “individual fabrication”, Ottobock offers the possibility of individualisation. Perhaps in the future, we will be able to generate solutions in cooperation with iFab that form a symbiosis of the user's wishes and the Ottobock design language. O&P professionals also offer further possibilities for individualisation of the socket design.

Users want more and more different colours and patterns. Why are they not offered?

In order to understand this, I have to elaborate a bit. The frames and surface finishing are created by hand. This is a complex process that we as a medical device manufacturer have to maintain over a long period of time. I learned how to paint cars, and I know what that means. You get a Porsche in the colour you want. It costs extra, and not a little. So there is no way to do this yet. However, this is not the first time we have heard about this topic and we have ideas on how to further implement individualisation requests. As with cars, you could work with a different technology instead of painting and offer a larger selection of hues. However, these should fit into the product portfolio and colour schemes. We also have to consider the durability and visual quality of our current products. The most beautiful joint is of little value if it gets totally scratched during the first walk.

How do you describe this line between design demands and feasibility?

Design is a purchasing criterion and a flagship for quality. In addition, it is not limited to the external form alone. Much is aimed at manufacturability, user-friendliness and the use of resources. There is little point in pushing through a design that drives up costs, for example. Industrial design is about a daily struggle for the best solution. Wearers don't want a “lump on the leg.” A beautiful and well-functioning product that you like to wear is an enrichment for your quality of life.

What design criteria are the most important in prosthetics?

User-friendliness above all else. A product that looks beautiful but doesn't work won't last. The often quoted design motto is “form follows function”! Nevertheless: A prosthesis is a very emotional product and is worn on the body. Design is the bridge to the human being. An overloaded product is unnecessarily confusing and often regarded as a foreign object. To mention one more design principle: The “MAYA principle” means “most advanced, yet acceptable.” It describes the need to meet people in their place and time, because perceptions only change gradually.

Is there still such as thing classic masculine or feminine design in prosthetics? And if so, what are the differences?

The concepts of classic masculine or feminine are blurred. There is no difference with regard to formal aesthetics, since body parts such as the calf or the hands are similar in their basic structure. We developed two colour schemes: Grey and technical, as well as a champagne hue combined with a brown hue, which is perceived as warmer and closer to the body.

A prosthesis must have the perfect design for everyone – for the teenager as well as for the pensioner. How are the differences reflected in the design?

Research and studies help us take such differences into account. A precise understanding of the target group is the most important thing, meaning who they are and what their everyday life looks like. Thus, the sneaker-wearing teenager will have a different requirement profile than the pensioner. What we use as design tools, among other things, are the design vocabulary derived from the human body and the requirements the product has to meet. Thus we employ a design vocabulary that ranges from restrained, quiet or rounded to more expressive, active or curvilinear.

Is it possible to design different prostheses for older and for younger people?

It is important to consider the person's mobility grade in our analysis. Differences such as age, height, weight, motivation, mobility, experience, environment and personal taste open up a wide corridor. This needs to be simplified. We reduce or increase form factors depending on the requirement profile. For example, we see that older people tend to resort to natural foam cosmetics, which they pull over the prosthesis. Younger ones hide the prosthesis less often.

Can you give a concrete example of such form factors?

With the Kenevo, a prosthesis for less active users, we have joined two circles. They appear calm and closed. With the more dynamic C-Leg, two circular segments are connected, which describe a drop shape and indicate a direction. The third level of dynamics, as with the Genium, is to form an ellipse from the circle, which appears more dynamic. In addition, the ellipse was tilted by 45 degrees to create an ascending diagonal. The sum of such details creates a more active and dynamic or a more stable and secure impression.

Which prosthesis is the best from a designer's perspective and why?

That's like asking a father which of his children he loves most! Each prosthesis serves a specific purpose. There are restrained models like the Kenevo and expressive models like the Genium X3 and the bebionic hand prosthesis. Personally, I am fascinated by the expressive models. But what fascinates me even more is what a prosthesis means to a person and what you can do with it.

Thank you!

Downloads

Draft of the new C-Leg design (Credit: Andreas Hogh / Ottobock)

Development of the C-Leg design (from left to right, Credit: Ottobock)

Increase in dynamics with the Kenevo (1), C-Leg (2) and Genium (3, from left to right)

The design of the new C-Leg

4 results out of 4